Pressure Wave Generators How It Works

Our pressure wave generators (PWG) are valveless electroacoustic devices - like extremely powerful audio speakers - that produce high-intensity acoustic power. Here is more information about this technology and how it works.

In this guide:

About Pressure Wave Generators

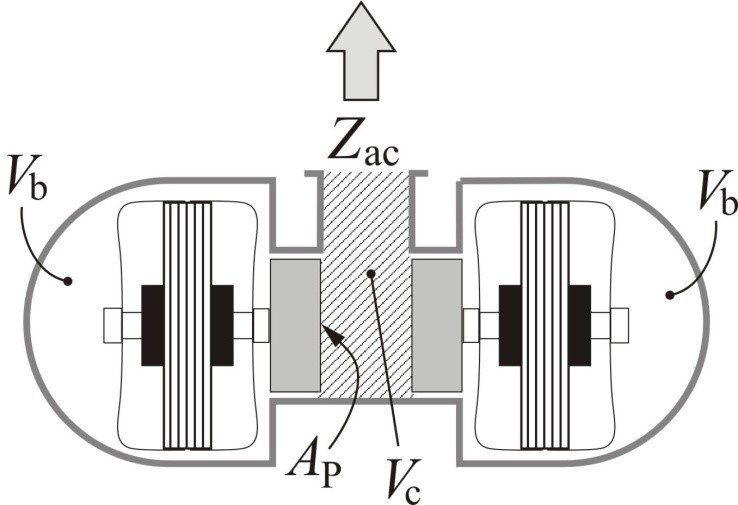

The below illustration shows schematically what’s inside a PWG. There are two robust linear reciprocating motors with pistons of area AP, both addressing a common space (the front or compression volume, VC). Each motor is enclosed by a back volume VB. The motors are wired in parallel and run by a common power supply, which causes them to alternately compress and expand the gas in VC and deliver acoustic power to the load ZAC. All of the pressure force on the back sides of the pistons, and part of the force on the front side (that part that is in phase with displacement) act as gas-spring forces on the motors, raising their natural frequencies. It is important for the user to know how much gas spring is provided by the load, to determine the natural or ‘resonance’ frequency of the system and ensure that the PWG is run at or near this frequency. “Off-resonance” operation is only recommended when the power rating of the PWG far exceeds the power requirements of an application, and even then, caution is advised.

The linear Motors are Moving Magnet Transducers, Characterized by

The linear motors are moving magnet transducers, characterized by

- Transduction coefficient Bl in Newtons/Amp

- Electrical resistance of motor coil Re in Ohm

- “Mechanical resistance” Rm in N•s/m

- Coil inductance Le in Henrys

- Moving mass m in kg

- “Mechanical” (mostly magnetic) stiffness Km in N/m

The PWG as a whole is characterized by the aforementioned piston area AP and volumes VC and VB, plus the seal length (piston length) L, the front side and back side surface areas SC and SB, and the tiny annular gap between the pistons and the cylinders, which we call the clearance gap d. Together with the ratio of specific heats g = cP/cV of the working gas, these parameters define the dynamics and the efficiency of the PWG.