Linear Reciprocating Motors & Alternators How It Works

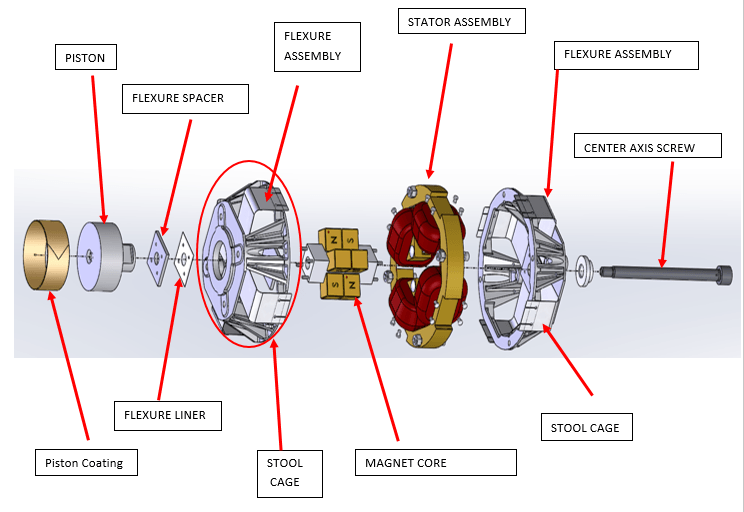

RIX’s linear motors & alternators are the driving force behind all our products. These are linear reciprocating devices that combine the unique flexing axial suspension with plunger-mounted, high-energy magnets and robust coil-over-iron stators. Here is more information about this technology and how it works.

In this guide:

Linear Reciprocating Motors, Alternators and Drivers

RIX’s acoustic drives are similar to a loudspeaker in your home stereo system. A voltage signal is supplied and the speaker moves back and forth in response, pushing and pulling air in time with the frequency of the electrical signal. The same principle applies here, though the device is a bit different. The magnets move, not the coil, and they are supported by unlimited-life metallic flexures instead of paper or plastic. Like a speaker, it needs no oil – an important advantage when using these devices in a cryocooler (cold oil is not useful!). Unlike a speaker, it pushes not air, but typically high-pressure helium (one of two gases that remains a gas below 77K). And because of that high pressure, the moving face area is smaller and stronger – a metal piston instead of a paper cone. The metallic flexures are designed to hold such a straight line of motion that the pistons can be machined with just microns of clearance to their matched cylinders and run without contact or wearing. One other difference with speakers is that they are designed for an inefficient but ‘flat’ response across a wide range of pitch frequencies. RIX’s are tuned to resonate at a single driving frequency (we use 50 or 60 Hz because it comes from the wall plugs!) to give high power and efficiency.

Motor Mode

- Alternating voltage is applied to the linear motor. Current flows through the motor windings, causing a magnetic field in the iron they surround.

- The applied field, oscillating due to the reversing electrical input, pushes and pulls on permanent magnets mounted on the moving assembly, (called the piston-plunger).

- When the applied voltage frequency is close to the resonant frequency of the motor and load combined, the piston oscillates and power is delivered to the acoustic load by phase separation of the current and piston displacement.

- Typically, when connected to an acoustic load like a cryogenic coldhead, helium gas is cyclically compressed and expanded relative to the mean (charge) pressure by the piston of the driver to power a thermodynamic cycle for refrigeration.

Alternator Mode

- Alternating pressure is applied to the piston. The force of the pressure (and associated gas flow) causes the piston to oscillate. The frequency of oscillation is a system variable – applied pressure frequency must be close to the system resonance for optimal performance.

- The oscillatory movement causes changing flux links between the magnets moving with the piston and the iron stator.

- The reversing flux changes in the iron induce voltage in the windings.

- If connected to a load resistance, the voltage causes current to flow and power to be delivered from the alternator.

- Power factor (phase of voltage and current) can be corrected by use of an appropriate capacitor in series with the alternator and load.